QT10-15 Full Automatic brick manufacture machine

$36,000.00

OT10-15 Fully-Automatic Block Machine Line

Advantage

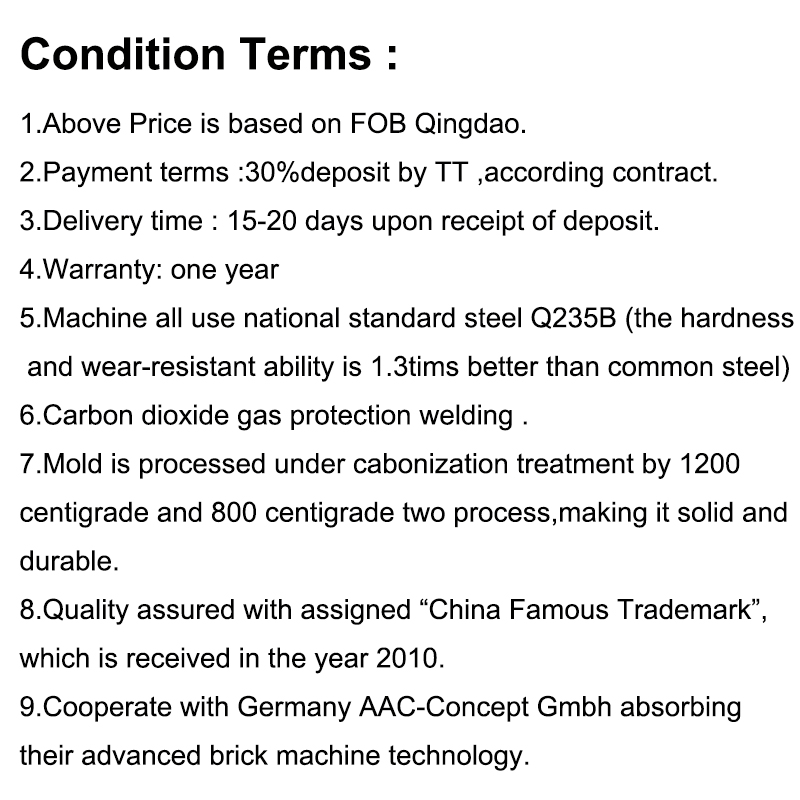

1.Material and welding:all material and spare parts seleted according international CE standard,Carbon dioxide protection welding will assure whole line stable running

2.Control PLC:we selete original Mitsubishi PLC combine with independently develop machine control program,assurestable and high-efficiency working status.

3.Switches and motor:Switches will use Japan Omron and France Schneider brand,motor will useSiemens or ABB brand

4.Hydraulic system:Hydraulic spare parts be ordered according our block machine characteristics from Taiwan

5.Material feeder:Rotary mixer type material feeding cart,finished products get higher density and strength.

6.Mould:newest heat treatment device assure longer mould life span.

7.Spare part:follow the machine shipment,we supply suitable wearing partsthe after-sale services will be faster.

描述

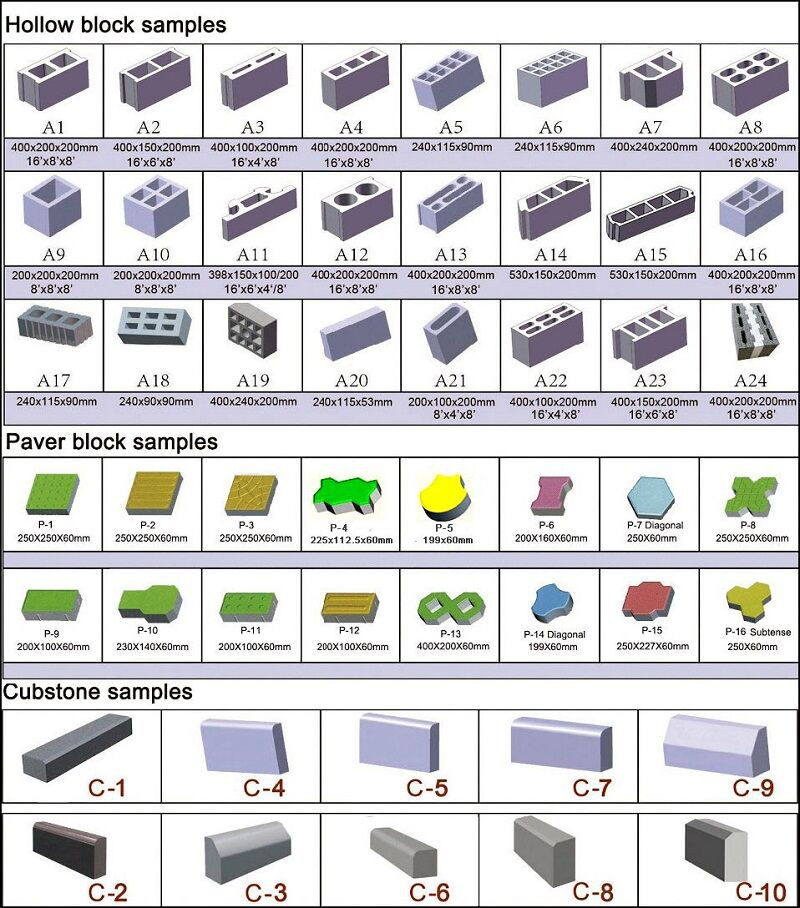

1. QT10-15 Full Automatic brick manufacture machine is latest developed equipment product, which is a special-purpose equipment for making building block making machine. The material of this machine can be flyash, slag, gangue or the others industrial waste, river sand, gravel, cement etc. Makes different sizes of hollow blocks, porous blocks, curbstone, pavement blocks, grass blocks, slope-protecting blocks, ring-tree blocks etc. If add color machine, it can make layering blocks.

make the simple production line with PL1200 batching machine, JS750 mixer,8m conveyor belt and stacker.

|

Technique Parameters

|

|

|

Machine power

|

44kw

|

|

Molding cycle

|

15-20 seconds

|

|

Hydraulic pressure

|

16-21 Mpa

|

|

Machine weigh

|

10000KGS

|

|

Overall size

|

9350*2320*2950mm

|

|

Voltage

|

According to your local voltage

|

|

Main Vibration Form

|

Platform Vibration

|

|

Pallet Size

|

1100*900mm

|

|

Applied Products

|

Concrete blocks, hollow/solid blocks, pavers, interlocking blocks , curbstone, colored pavers ,etc.

|

|

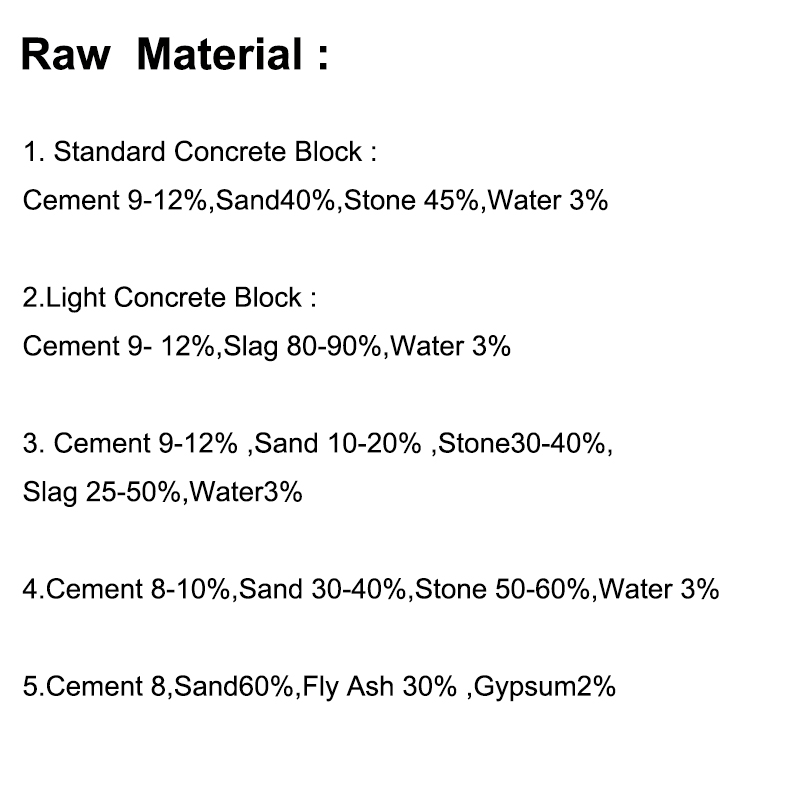

Raw Material

|

Crushed stone, sand , cement, dust, and fly ash, gravel, slag, and other raw material etc.

|

|

Capacity

|

||||

|

Items

|

Block size

|

Pcs/mould

|

Cycle molding

|

Pcs/day

|

|

Hollow Block

|

400*200*200mm

|

10

|

16-20s

|

18000

|

|

Porous Block

|

240*115*90mm

|

28

|

15-20s

|

67200

|

|

Standard Block

|

240*115*53mm

|

52

|

15-17s

|

124800

|

其他信息

| 重量 | 10000 公斤 |

|---|---|

| 尺寸 | 935 × 232 × 295 厘米 |

| Color | Black, Blue, White |

| Size | *2950mm |

| Production Capacity | 4480 pcs/8hours2500 pcs/8hours∣3400 pcs/8hours |

| Brick size | 400*100*200 mm∣ 400*120*200 mm∣200*100*60 mm |

| Warranty of core components | 2 years |

| Voltage | Local Voltage |

| Products | concrete hollow/solid/pavers/curbstone blocks |

| Worker | 1-3 |

admin –